Richard L Stevenson and Dr Erika Palfi

Globally, the Anaerobic Digestion (AD) and biogas industry is on a rapid annual growth trajectory of between 8% to 22% out to 2030 (IEA, 2023). In the UK, it produces 24TWh of energy – broadly equivalent to Scotland’s annual electricity demand – and it is poised to surpass nuclear (~40TWh) as a low carbon energy provider by 2029 (ADBA, 2024). This milestone underscores the industry's increasing importance in the wider energy landscape and also alludes to a significant and growing negative emissions opportunity – both key takeaways from this year's World Biogas Expo held at the NEC Birmingham on 10-11 July 2024.

Organised by the Anaerobic Digestion and Bioresources Association (ADBA) and the World Biogas Association (WBA), the event showcased the sector's rapid expansion and its potential to drive the future of sustainable energy. SCCS popped along to find out more about all things AD and biogas and their potential to deliver CO2 reductions and removals. Before that, though, some context.

AD & Biogas

Biogas is a mixture of predominantly methane and CO2 produced by the anaerobic digestion of organic matter. The main production pathways for biogas include landfill gas recovery systems, wastewater treatment plants, and AD plants, purpose-built biodigesters that treat a combination of dedicated energy crops and organic waste such as food waste, manure and sewage sludge. Biogas is often combusted on-site to produce heat and/or electricity in a combined heat and power (CHP) configuration.

Biomethane

By removing the inherent CO2, biogas can be ‘upgraded’ to biomethane, a direct replacement for fossil natural gas. While chemically identical to fossil methane, biomethane is produced from fresh organic matter, making it a renewable source of energy. Hence it is also known as renewable natural gas or ‘green gas’. It is produced at AD plants across the UK where it can then be used locally or injected into the gas grid, helping to simultaneously decarbonise the grid and enhance energy security while providing a solution for dealing with organic waste.

Schematic showing the flow of carbon through the AD-to-biomethane or “Green Gas” production process. Source: Future Biogas (2023). Green Gas & Carbon Capture

Bio-CO2

The CO2 released from the combustion of biogas and biomethane upgrading process is biogenic CO2, or bio-CO2. Different to its fossil equivalent, bio-CO2 does not add carbon to the atmosphere. Rather, it is part of the natural ‘short’ carbon cycle whereby atmospheric carbon is removed by living organisms, e.g. plants, during their growth phase, is then passed on up the food chain, and thereafter recycled via organic processes. Bio-CO2 can displace fossil CO2 in industrial use settings and, when securely stored in the geological subsurface or in certain products via specific processes, it can result in a net removal of atmospheric CO2, i.e. negative emissions.

Schematic showing the process of atmospheric CO2 removal via Bio-CCS (AD + CCS). To qualify as negative emissions, two principles must be met: (1) carbon must be captured from the atmosphere; (2) the carbon must be durably stored and must exceed any process lifecycle emissions. Source: Zero Emissions Platform (2020). Europe needs a definition of Carbon Dioxide Removal

Negative emissions potential

Bio-CO2 from AD-biomethane production is predictable and relatively cheap and easy to capture, due to its high purity and high concentration. Just over 130 AD-biomethane plants in the UK currently produce around 1Mt/yr, far exceeding current industrial demand of around 600kt/yr. And projections suggest that this could rise to 8.3Mt/yr by 2028, if all UK unavoidable organic waste were to be processed via AD. Accounting for increased industrial use, this would still leave around 7.4Mt/yr for removals, more than enough to meet the UK’s 2030 target of 5MtCO2e/yr of greenhouse gas removals (GGR), and would contribute just under one-third of the 2035 GGR target of 23MtCO2e/yr (ADBA, 2023).

This significant bio-CO2 resource remains, however, largely untapped, with less than 10% actually captured, utilised or stored. This is predominantly due to two barriers: cost and perception. Installing and operating carbon capture systems incurs additional cost and there remains a negative market perception of waste-derived CO2. (ADBA, 2023).

Springhill Nurseries AD Plant

A pre-expo visit to the Springhill Nurseries AD Plant, owned and operated by Vale Green Energy, provided an insight into the full-chain operational intricacies of biogas, biomethane and bio-CO2 production, demonstrating the versatility of the technology and its potential to both reduce and remove atmospheric emissions.

Commissioned in 2013, and the first gas-to-grid plant injecting into the Wales and West Network, the 1.5MW plant processes up to 70 tonnes of agricultural feedstock daily, includes a 500kW CHP biogas engine and Pentair gas-to-grid technology capable of exporting up to 9000m³/day of biomethane into the national grid. The facility supplies power and heat for its own operations, which include vast on-site greenhouses producing tomatoes and salad onions. It also generates around 80kt/yr of digestate, an organic fertiliser, which is then sold on to farmers. This displaces fossil-based synthetic alternatives and brings soil conditioning and biodiversity benefits, too.

Via a Pentair 2-stage membrane/cryogenic separation system, the plant also produces up to 3kt/yr of bio-CO2(99.9% purity), some of which is used as a gaseous natural fertiliser in the greenhouses, while the remainder is currently sold on to the food & drink sector. Vale Green is also now reportedly considering options pertaining to carbon removals.

Springhill’s two AD (biodigester) tanks. Image credit: SCCS

Springhill’s Pentair biogas processing system. Image credit: SCCS

Springhill’s Pentair CO₂ separation/biomethane upgrading system. Image credit: SCCS

Thoughts from the floor

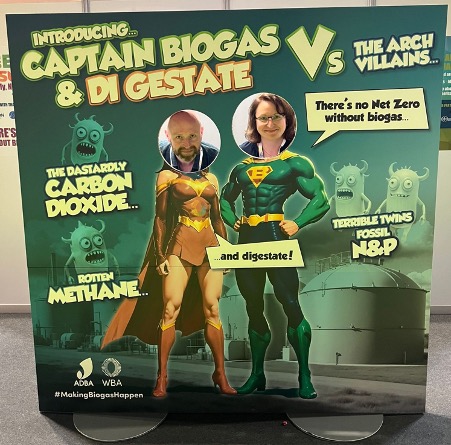

The site visit and the expo gave us a front row view into how the sector is developing. With environmental matters very much front and centre for what is largely a sub-section of the agricultural sector, the climate credentials for AD, biogas, and biomethane are many (as Captain Biogas and Di Gestate will attest – see below). Notwithstanding challenges around financing and permitting, and buoyed by recent high-profile investments by BP, TotalEnergies, and Shell, the overall outlook is positive.

Image credit: SCCS

Against a background of rapidly developing voluntary and compliance carbon market mechanisms, the value and perception of this considerable bio-CO2 resource is also changing. With CO2 removal prices currently as much as £300/tonne (Danish Energy Agency, 2024), and high-profile bio-CO2 removal projects from the likes of Future Biogas, Carbon Capture Scotland and Acorn Bioenergy pointing towards the viability of subsidy-free business models in the UK, opinions (and actions) are clearly starting to shift. Industry feedback also suggests growth, with examples including AD plants as small as 50GWh capacity now installing carbon capture systems, where the cut-off point, until very recently, sat at around the 100GWh mark.

SCCS supports forms of bioenergy that process unavoidable organic waste streams and sustainable biomass. AD and biogas/biomethane production, and carefully considered use of the resulting bio-CO2 are great examples of this and they can all play a significant part in tackling the climate crisis and more.

Recent work by SCCS also points towards a large - and growing - bio-CO2 prize in Scotland, covering bioenergy (biomass, energy from waste, AD CHP/biomethane-to-grid) and non-energy sources (distillery fermentation).

SCCS (2024). Onshore and inshore storage of carbon dioxide

SNZR (2023). Scottish Net Zero Roadmap

SCCS (2018). Negative Emission Technology in Scotland: carbon capture and storage for biogenic CO₂ emissions

Links:

Anaerobic Digestion and Bioresources Association (ADBA)

World Biogas Association (WBA)

Vale Green Energy Springhill Nurseries AD Plant

Pentair Springhill Farms, UK